Creating personalized and unique wooden wall decor has never been easier, thanks to advancements in laser machine technology.

Whether you’re a seasoned DIY enthusiast or a beginner looking to add a personal touch to your home, a laser machine can transform your creative ideas into stunning wall art.

This comprehensive guide will walk you through the process of designing, crafting, and finishing your own wooden wall decor using a laser machine.

Materials and Tools You’ll Need

Before diving into your DIY project, gather the necessary materials and tools to ensure a smooth and successful process.

Materials:

Wood:

Choose from plywood, MDF, hardwood, or reclaimed wood depending on your design and budget.

Adhesive:

Wood glue or double-sided tape for assembling pieces (if needed).

Finishes:

Stain, paint, or varnish to protect and enhance your decor.

Tools:

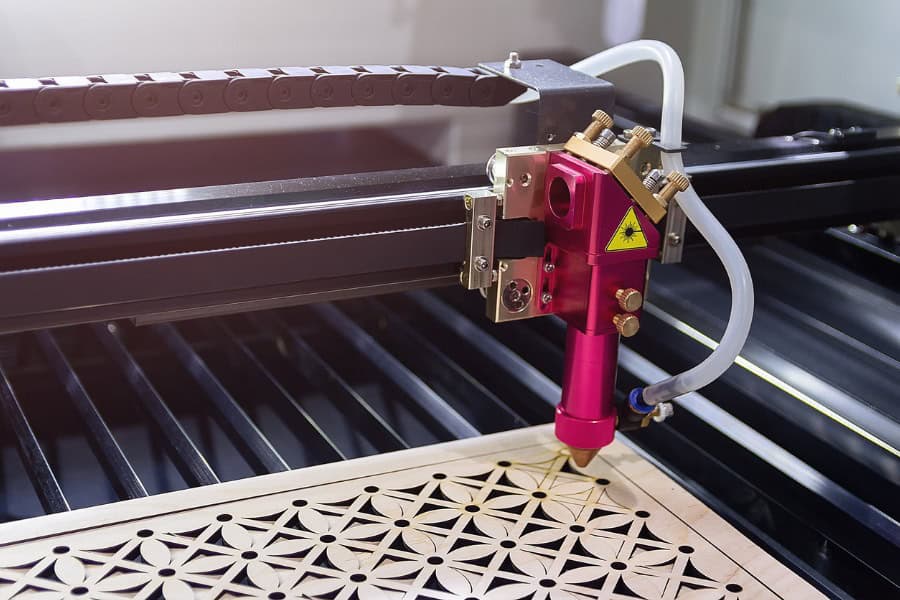

Laser Machine:

A wood laser cutter/engraver capable of handling the thickness and type of wood you’ve chosen.

Design Software:

Vector-based programs like Adobe Illustrator, CorelDRAW, or free alternatives like Inkscape.

Computer:

To create and send designs to the laser machine.

Safety Gear:

Protective eyewear and proper ventilation to handle fumes and debris.

Additional Tools:

Sandpaper for smoothing edges, clamps for securing pieces during assembly, and brushes or cloths for applying finishes.

Step-by-Step Guide to DIY Wooden Wall Decor

Creating wooden wall decor with a laser machine involves several key steps, from designing to finishing. Follow this step-by-step guide to achieve professional-looking results.

1. Ideation and Design

Begin by brainstorming ideas for your wall decor. Consider the following:

Theme:

Modern geometric patterns, nature-inspired motifs, personalized quotes, or abstract art.

Size and Shape:

Determine the dimensions based on your wall space and desired impact.

Complexity:

Choose a design that matches your skill level and the capabilities of your laser machine.

Design Tips

Simplicity:

Start with simple designs if you’re a beginner.

Layering:

Create depth by designing multi-layered pieces.

Symmetry and Balance:

Ensure your design is visually appealing with balanced elements.

Once you have a concept, use design software to create a vector-based file (e.g., .SVG, .AI) that the laser machine can interpret.

Pay attention to line thickness, engraving areas, and the overall layout.

2. Preparing the Wood

Selecting the right wood and preparing it correctly is crucial for achieving the best results.

Choosing the Right Wood

Plywood:

Affordable and available in various thicknesses; ideal for intricate designs.

MDF (Medium-Density Fiberboard):

Smooth surface, great for detailed engraving but less durable.

Hardwood:

Offers a premium look and durability; suitable for high-end decor.

Reclaimed Wood:

Adds character and sustainability to your projects.

Preparation Steps

Cutting to Size:

Ensure your wood pieces fit within the laser machine’s working area.

Sanding:

Smooth any rough edges to prevent splintering and ensure clean cuts.

Cleaning:

Remove dust and debris to avoid interference with the engraving process.

3. Setting Up the Laser Machine

Proper setup of your laser machine is essential for precise and effective engraving and cutting.

Steps to Set Up

Software Configuration:

Import your design file into the laser machine’s software. Adjust the layout to fit the wood piece.

Material Settings:

Input the correct settings for your specific wood type and thickness. This typically includes power, speed, and frequency parameters.

Focus the Laser:

Ensure the laser is properly focused for optimal cutting and engraving quality.

Test Run:

Conduct a test on a scrap piece of wood to fine-tune settings and verify the design alignment.

Safety Precautions

Ventilation:

Use the laser machine in a well-ventilated area to disperse fumes and smoke.

Protective Gear:

Always wear safety goggles designed for your laser’s wavelength.

Fire Safety:

Keep a fire extinguisher nearby and never leave the machine unattended during operation.

4. Engraving and Cutting

With everything set up, it’s time to bring your design to life.

Engraving Process

Engraving Depth:

Decide whether you want a shallow etch or a deeper engraving based on your design needs.

Details:

Intricate designs may require multiple passes with varying settings to achieve the desired depth and clarity.

Monitoring:

Keep an eye on the process to address any issues like excessive burning or incomplete cuts.

Cutting Process

Precision Cutting:

The laser will accurately cut out the shapes based on your design.

Edge Quality:

High-quality settings will result in smooth, clean edges without charring or roughness.

5. Assembly and Finishing

After engraving and cutting, assemble any multi-layered pieces and apply finishing touches.

Assembly Steps:

Layering:

If your design involves multiple layers, align and glue them carefully to create depth and dimension.

Securing:

Use clamps or weights to hold the pieces together while the adhesive sets.

Finishing Touches:

Sanding:

Smooth any rough edges or surfaces that may need refinement.

Staining or Painting:

Apply stains to enhance the wood’s natural beauty or paint to add color and vibrancy.

Sealing:

Protect your decor with a clear varnish or sealant to prevent damage from moisture and wear.

Mounting:

Attach hooks, wires, or brackets to hang your wall decor securely.

Creative Ideas for Wooden Wall Decor

Let your imagination run wild with these creative ideas to inspire your next laser-cut wooden wall project:

Geometric Patterns:

Create modern art pieces with intricate geometric shapes and patterns.

Nature-Inspired Designs:

Engrave leaves, trees, animals, or floral motifs for a natural aesthetic.

Custom Quotes:

Personalize your space with engraved quotes, names, or meaningful messages.

City Skylines:

Capture the essence of your favorite city’s skyline in a minimalist wooden outline.

Mandala Art:

Design detailed mandalas for a serene and meditative visual appeal.

3D Relief Art:

Experiment with layered designs to add a three-dimensional effect to your wall decor.

Interactive Pieces:

Incorporate movable elements or hidden compartments for a unique and functional touch.

Tips for Successful Laser Engraving

To ensure your DIY wooden wall decor turns out beautifully, keep these tips in mind:

Start Simple:

Begin with straightforward designs to build your confidence and understanding of the laser machine.

Choose High-Quality Designs:

Invest time in creating or sourcing high-resolution vector files for crisp and clear engravings.

Test Regularly:

Regularly test your settings on scrap wood to avoid wasting materials and to refine your process.

Maintain Your Machine:

Keep your laser machine clean and well-maintained to ensure consistent performance and longevity.

Experiment with Materials:

Don’t limit yourself to one type of wood; explore different textures and grains to find the best fit for your projects.

Stay Inspired:

Look for inspiration online, in nature, and through other artists to continually evolve your designs and techniques.

Safety Considerations

Working with a laser machine requires strict adherence to safety protocols to prevent accidents and ensure a safe working environment.

Proper Ventilation:

Always use your laser machine in an area with adequate ventilation to manage fumes and smoke.

Protective Gear:

Wear appropriate safety goggles and ensure that your workspace is free from flammable materials.

Supervision:

Never leave the laser machine unattended while it’s operating.

Fire Prevention:

Keep a fire extinguisher nearby and be prepared to act in case of a fire emergency.

Regular Maintenance:

Perform routine checks and maintenance on your laser machine to ensure it operates safely and efficiently.

Conclusion

DIY wooden wall decor using a laser machine is a rewarding and creative endeavor that allows you to personalize your living space with unique and meaningful art pieces.

By following this guide, you can confidently navigate the process from design to finished product, leveraging the precision and versatility of laser technology to bring your artistic visions to life.

Whether you’re enhancing your own home or creating bespoke gifts for loved ones, laser-cut wooden decor offers endless possibilities for creativity and self-expression.

Embrace the blend of traditional craftsmanship and modern technology, and enjoy the satisfaction of crafting beautiful, customized wall art that truly stands out.